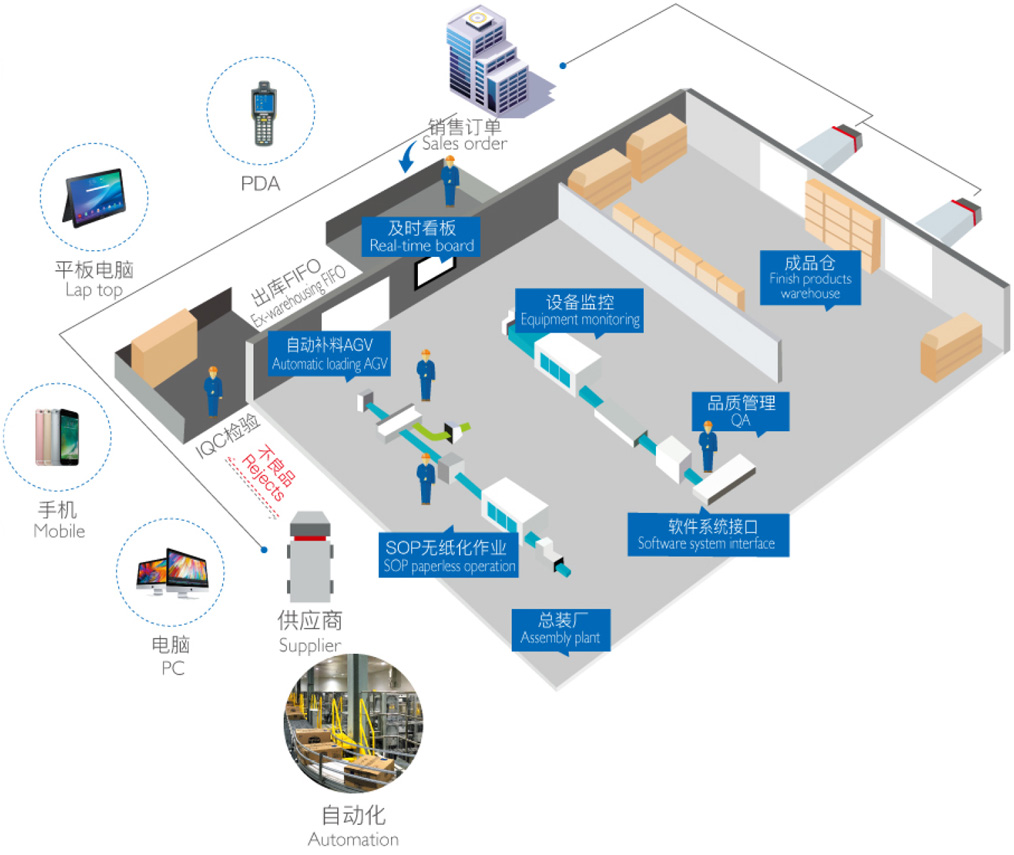

Intelligent warehouse management system includes warehouse business, ex-warehouse business, warehouse transshipment, stock transshipment and virtual warehouse management. According to production scheduling of MES system, the system automatically calculates the demands of the first set of materials of the production line; then pushes to warehouse workers’ hand-held terminal and stock preparation board, also guides stock preparation of first set and distribution. After the normal production, the system will get the demand condition of emergency material by logical data of returned machinery equipment capacity, practical buckle material numbers, discarded quantity, the priority of production. Material preparation commands are informed or pushed by the way of board, email and message.

System Functions

■ ERP data interface

■ Basic information maintenance, barcode printing

■ IQC inspection, material warehousing, ex-warehouse, allocation

■ Line side warehouse material management (optional)

■ Warehousing, ex-warehouse of finished products

■ Inventory verification, inventory warning and tracing