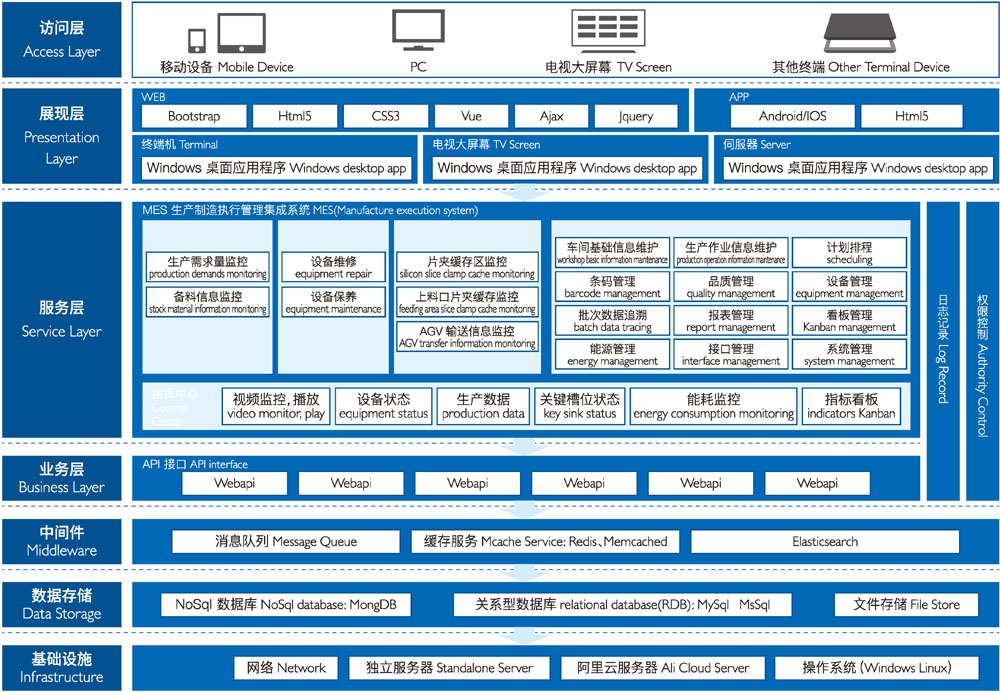

MES (Manufacturing Execution System) lean manufacturing execution management system is the basis for enterprises to build intelligent factories, and it is a management means for enterprises to implement rapid decision-making and realize agile workshop production. The MES system can provide quality control, equipment failure analysis, report management, production management, process management, product maintenance/scrap processing, data traceability, production scheduling, product tracking, data analysis, station data query, Early warning management, equipment maintenance, external interface and other functions, by using of a unified data warehouse and network technology to provide workshop information management services and business control for production departments, maintenance departments, quality inspection departments, process departments, logistics departments, etc. By emphasizing the overall optimization of the manufacturing process, the MES system helps enterprises implement complete closed-loop production to realize intelligent manufacturing and management.

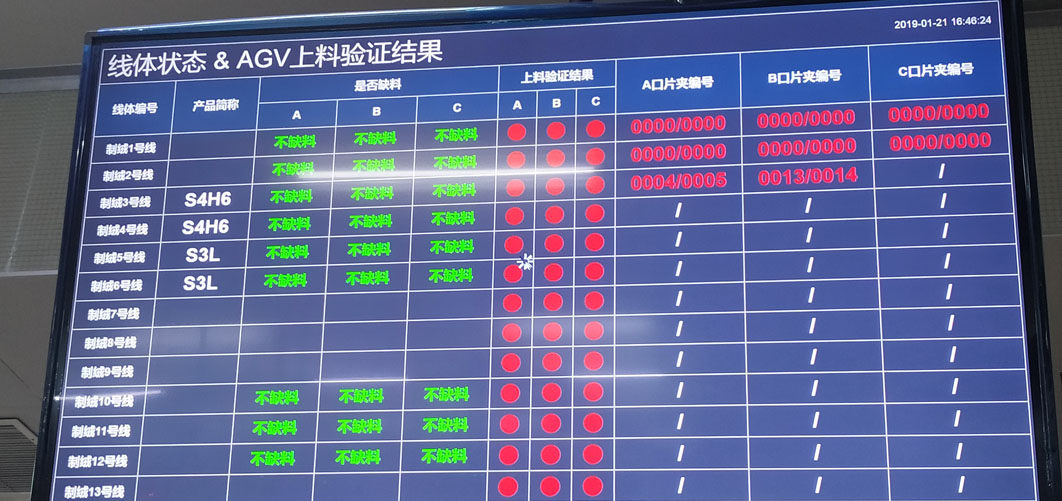

1. Production Information Visualization

2. Product Traceability

3. Lean production

4. Intellectualization of Management Process

5. Controllability of Production Cost

6. Assessment Digitization

7. Authentic and Reliable Data Information

8. Production Automation in Whole Course