Cylindrical battery automatic assemly line includes a complete production process of automatic sorting, inserting into holder, screw punching, welding, assembling, testing and packaging. The main process includes resistance welding process, ultrasonic aluminum wire boning process, etc. The cell series include 18650, 21700, 32131 as well as 4680 large cylindrical cells.

1、Capacity: Battery cells processing capacity of a single line is 200~300PPM.

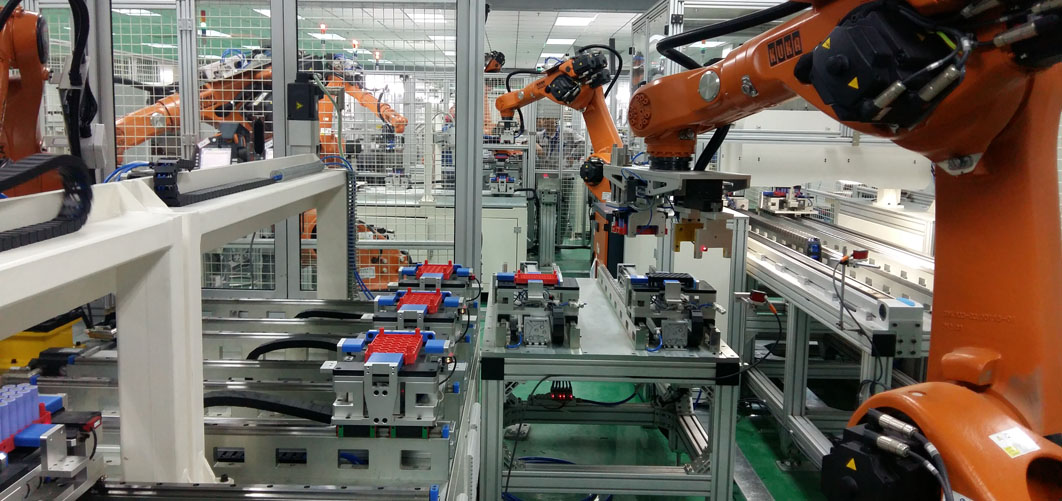

2、High automation: The robots can automatically perform the process of loading,sorting,inserting into holder,screw fastening,welding,assembling and testing. The material can be transfered through AGV.

3、High reliability design: The robot is used for realizing the core functions. The double-station servo slide table design is adopted between each station, which has the characteristics of high precision and easy changeover. Combined with the buffer station, it can take in the product fluctuations of the whole line to improve production flexibility. The welding station adopts imported equipment to ensure the welding quality.

4、Flexible design of production line: In case of abnormality in the upper/next process, the product can be manually put into/taken out from the transplanting platform, and the cycle can be greatly shortened during debugging. When the product process changes, some workstations can be replaced to realize process switching.

5、Stability design: It abundantly adopts six-axis standard industrial robots to improve automatic level and stability, like that the speed of battery cells sorting and shell entering is quick and in key position.

6、MES system: The MES data management system runs through the entire production process of the factory, leading the control of all levels of the entire production process, and traces the refined control of production process parameters, quality status, and material status,etc.